Hyperspectral Imaging at 1000 frames per second

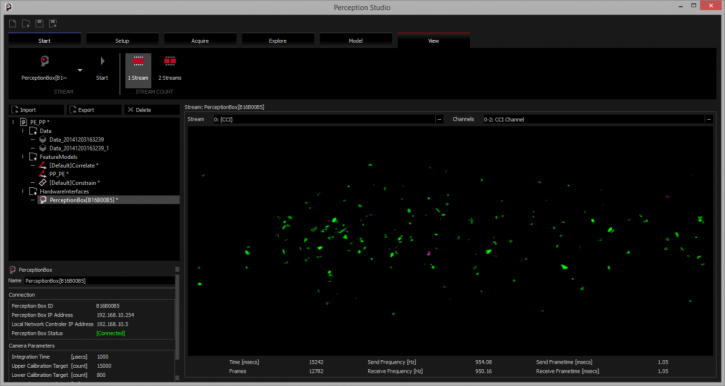

The Perception System is a complete data processing solution for inline hyperspectral imaging in industry and can process data with 1000 frames per second and more.

Hereafter we present examples of Chemical Color Imaging, testing the Perception System with 1000 frames per second. While state of the art systems provide processing power of around 25 million SP/s (spectral points per second) a Perception System can process up to 150 million SP/s.

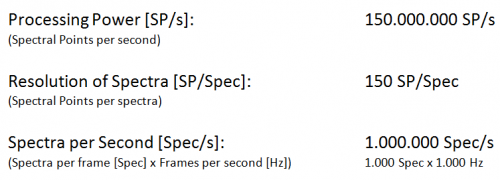

Only with a Perception System even high resolved hyperspectral cameras with high scan rates can be implemented for industrial inline applications. Depending on the camera, the formula below can roughly be used to estimate the spectra per second that can be processed with a Perception System.

![]()

Example:

To know the resolution that can be processed with a Perception System can support to choose the ideal camera to solve an application. e.g. Using spectra with 150 spectral points per spectra (150 pixels spectral resolution on the sensor) allows to process 1 million spectra per second. This means that a camera with a resolution of 1.000 px (spatial) and 150 px (spectral) working at a frame rate of 1.000 fps (frames per second) can be used.

By reducing the "Resolution of Spectra" the scan rate can be dramatically increased.

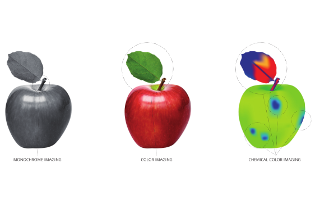

The examples below were generated by applying Chemical Color Imaging. Chemical Colors interpret molecular information by color information. This means that different colors represent different chemical properties. A Perception System allows implementing Chemical Color Imaging for industrial inline applications.

![]()

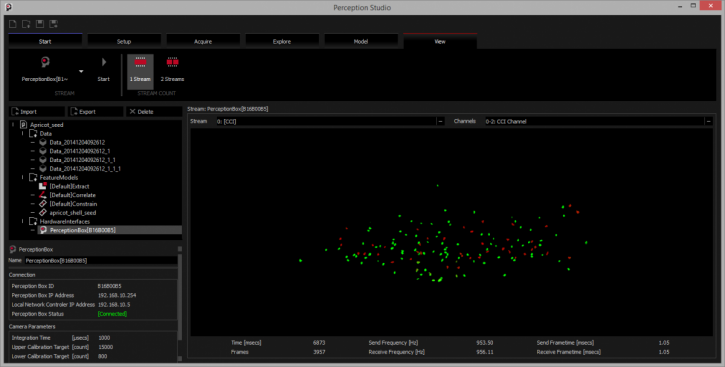

Sorting apricot seed from kernel shell

Together with a customer we showed how to differentiate between kernel shells and seeds of apricots. Beside the detection of impurities like kernel shells, one of the challenges was also to identify seeds with and without skin as good material. Therefore a push-broom hyperspectral camera working in the NIR was mounted on a machine with 700mm working width. To ensure a profitable application it was required to scan with around 1.000 frames per second.

First impressions could be shown in less than one hour. This is one of the most important strengths of a Perception System. - An application just needs to be configured instead to be developed from scratch. This has several advantages against the state of the art development process:

- Within minutes first impressions regarding the solvability of an application can be shown.

- Only with a few hours of work, first sorting results can be evaluated.

- Existing machinery can be used.

- Depending on the application, a first machine can be tested within days.

- Therefore a very short time to market is possible.

![]()

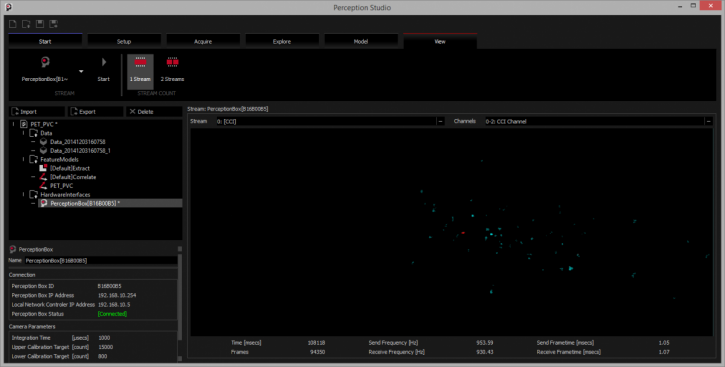

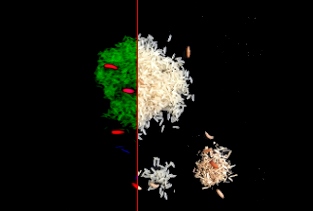

Detecting PVC in a stream of PET-flakes clear

Another application that was solved on this day was the monitoring of transparent PET flakes to detect impurities like PVC. Also here the reliable identification of impurities could be shown at a scan rate of 1 KHz.

![]()

Separating PE-flakes from PP-flakes

Also a well working application was the separation of PE-flakes and PP-flakes. The Perception System outputs multiple Chemical Color streams or multiple feature streams (monochrome stream for each feature). Therefore various plastics can be reliably identified in the same process step.

Chemical Color streams and/or monochrome streams of the Perception System can be processed by the customer's machine vision system. As a consequence the customer can integrate a hyperspectral camera into a sorting machine that is already used for color sorting. Furthermore by Chemical Color Imaging the customer is able to combine molecular information with the color information of objects to generate a more sophisticated sorting decision.

![]()

Hyperspectral Imaging - Setup

The Perception System was working together with a hyperspectral camera of the German manufacturer inno-spec mounted on a machine with 700mm working width and 2.5 m/s transportation speed. The hyperspectral camera has a resolution 320 pixels (spatial) and 256 pixels (spectral) and works with 330 fps (frames per second). To run the camera at 1000 fps a ROI (region of interest) in the spectral domain was preset.

About Perception Park

Feel Free to Contact us

Address

A-8010 Graz, Wartingergasse 42

Phone

+43 670 355 8358

E-mail

info@perception-park.com